AskHACCP: Listeria in Retail Establishments: Why “Clean” Isn’t Always Safe

- AgriForaging Compliance Services

- Oct 29, 2025

- 4 min read

Updated: Oct 30, 2025

This article is part of the AskHACCP Listeria Series, focused on bringing real-world compliance guidance to retail and small processing environments.

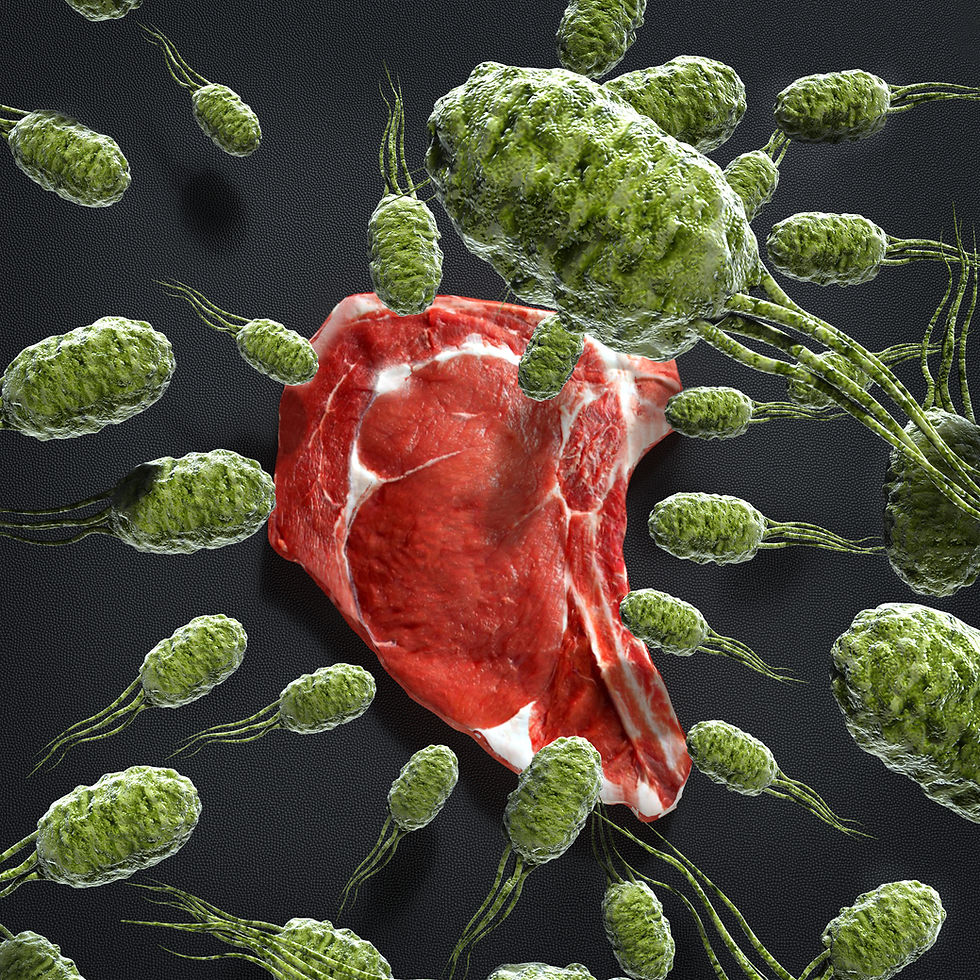

Walk into most retail food spaces and you will see surfaces that shine, mops that smell like sanitizer, and drains that run clear. But Listeria monocytogenes does not care about appearances. It survives in cold, wet environments and hides in the places most operators never think to check. A spotless prep area can still harbor a pathogen that quietly grows at refrigerator temperatures and moves from drain to slicer to ready-to-eat food without being seen.

Listeriosis can cause severe illness, particularly in pregnant people, older adults, and those with weakened immune systems. The consequences are serious even when the bacteria are invisible.

This is the difference between being visually clean and being microbiologically safe.

Where Listeria Lives

Listeria thrives in moisture, biofilms, and hard-to-reach spaces. It can attach to stainless steel, plastic, and rubber gaskets, then resist normal cleaning. Once it finds a niche, it stays.

🧠 Biofilm: A thin, sticky layer that bacteria form on surfaces to protect themselves. Once it builds, regular cleaning will not remove it.

Common retail harborage sites include:

Floor drains and the grout surrounding them

Undersides of prep tables and equipment legs

Slicer handles, push plates, and seams around guards

Cooler door gaskets and condensate lines

Areas where water collects or condensation drips

Even a small amount of standing water can keep Listeria alive. Because it tolerates salt and cold, refrigeration slows it down but does not stop it.

“A surface can look spotless and still harbor Listeria.”

Why Retail Is High Risk

Retail facilities are especially vulnerable because they mix product types, staff roles, and cleaning responsibilities.

Workers often move between raw and ready-to-eat areas without clear zoning

Equipment is shared between shifts and departments

Drains are rarely treated as food contact surfaces even though aerosols and splashes spread contamination

Cleaning tools are reused without proper drying or segregation

🧠 Ready-to-Eat (RTE): Food that will not be cooked again before it is eaten. Once a food is cooked, cured, or assembled for sale, it becomes RTE and must be kept free from Listeria contamination.

These small oversights create ideal conditions for cross-contamination. A retail slicer used for both cooked ham and raw cheese, or a shared drain under a prep table, can become the single point of exposure that leads to illness.

🧠 Cross-contamination: When bacteria move from one surface or product to another through tools, hands, gloves, or splashes.

The Regulatory View

Both the FDA Food Code and USDA FSIS identify Listeria as the primary post-lethality concern in RTE foods. For retail stores and markets, inspectors are watching how sanitation is organized, not just whether it is done.

🧠 Post-lethality exposure: The period after cooking or curing when food can be recontaminated before packaging or display.

Inspectors look for:

Defined sanitation zones

Documented cleaning frequencies

Drain and floor maintenance protocols

Verification records showing sanitizer concentration and contact time

Separation of raw and finished product handling areas

A well-documented cleaning program is as important as the cleaning itself. When a Listeria finding occurs, regulators trace whether it was an isolated event or evidence of a system that never controlled moisture or temperature effectively.

Steps That Make a Real Difference

Treat drains as risk zones. Clean and sanitize them daily, not weekly. Use tools dedicated only to drain work.

Revisit airflow and condensation. Water on ceilings or pipes can drip directly onto food contact surfaces.

Dry tools and surfaces completely. Listeria needs water to grow. Eliminate it wherever possible.

🧠 Water activity (aW): A measure of how much water is available for bacteria to grow. Even a damp floor or cloth can be enough for Listeria to survive.

Verify sanitation. Use ATP testing or environmental swabs to confirm that cleaning worked, not just that it was done.

🧠 ATP Testing (Adenosine Triphosphate): A quick test that measures leftover organic matter on a surface. ATP is an energy molecule found in all living cells such as food residue, bacteria, yeast, and mold. High ATP means the surface was not fully cleaned, even if it looks clean.

🧠 Environmental Swab: A sterile swab used to collect samples from surfaces to test for bacteria such as Listeria.

Record the work. Logs, checklists, and photos establish due diligence if questions arise.

Small changes in workflow, such as separating raw and RTE cleaning tools or sanitizing drains before floors, can close the gap between clean and safe.

Why This Matters

Listeria is not just a federal buzzword. It is one of the few pathogens that can survive the full retail day in cold, wet, and hidden places. Protecting against it protects both your customers and your business reputation. Real control starts with understanding where it hides and building daily habits that keep it from coming back.

Read the next article in the AskHACCP Listeria Series (coming soon).

AskHACCP Hotline

AskHACCP helps retailers and small processors translate science into daily practice. Have a question about Listeria control or sanitation zoning? Call 845-481-0820 or visit agriforaging.com/ask-haccp.

Comments